Lifter-Free and Tune-Up (LFTU)

![]()

Does your car engine rattle or make a tick, tick, tick (ticking) noise on start-up?

Lifter-Free & Tune-Up will help. It dissolves and dislodges harmful varnish and carbon deposits that accumulate within and around hydraulic lifters and cam followers without causing any damage to oil seals or gaskets.

Nulon Lifter Free & Tune-Up quietens lifters that are noisy during the first few minutes after start-up or during normal driving. The advanced cleaning formula safely softens and removes carbon and sludge deposits which are the major cause of noisy lifters.

Hydraulic lifter noise can be caused by several different factors

- Carbon particles blocking lifters

- Sludge, wax or varnish deposits causing sticky/noisy lifters

- The use of incorrect engine oil viscosity

- Mechanical damage to camshaft or lifter

- Broken parts within the lifter, e.g. relief valve springs

Nulon Lifter Free & Tune-Up can be used to correct causes 1 and 2 above. It can also be used as a diagnostic tool. If a lifter is still noisy 14 days or 500 km after using this product, it can be assumed that previous mechanical damage has caused the lifter noise.

The lifters should be removed and inspected or replaced.

Pack sizes

- Quietens noisy hydraulic lifters/cam followers

- Suitable for all petrol, diesel & LPG engines

- Cleans oil galleys in hydraulic lifters

- Removes sludge & soft carbon

- Frees up sticky lifters

- Will not affect oil viscosity

After changing engine oil and filter, add 1 bottle per 5 litres of engine oil capacity. Leave in the engine until the next oil change is due. NOTE: Safe to use with all types of engine oils.

For advice, contact a Poisons Information Centre (Phone e.g. Australia 131 126; New Zealand 0800 764 766) or a doctor (at once).

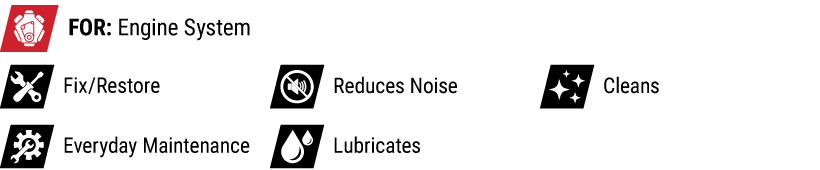

Fix/Restore

Bring your car back to life.

When issues arise, Nulon Fix & Restore engine and fuel treatments assist in returning your vehicle to normal operation. Whether it's addressing rough idling, diesel fuel issues, engine leaks, sludge build-up, or gasket failures, these products restore smooth operation by cleaning critical engine and exhaust components and resolving the root cause of common performance problems. Get back on the road with confidence, with Nulon’s premium range of engine and fuel treatments.